How Does Steel Backing Compare to Other Materials in Terms of Strength and Durability?

Steel backing is a common component in many industrial and automotive parts, providing structural support to materials like brake pads, gaskets, and friction linings. Its ability to withstand stress, heat, and wear makes it a go-to choice, but how does it stack up against other backing materials like aluminum, brass, plastic, or composites? Understanding the differences in strength and durability helps choose the right material for specific needs. Let’s break down how steel backing compares to other options.

What Is Steel Backing?

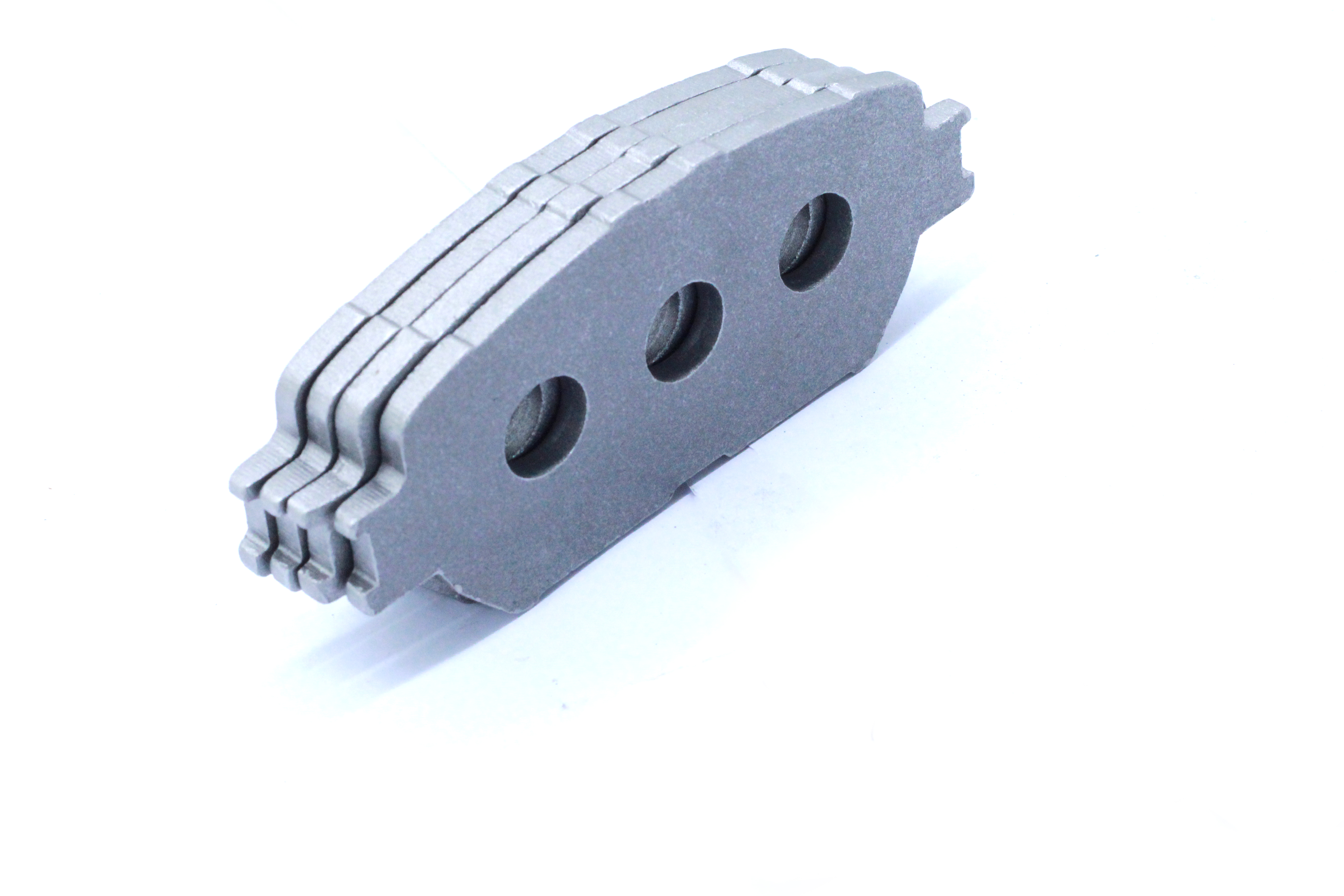

Steel backing refers to thin sheets or plates of steel used to reinforce softer materials (like friction pads or gaskets). It adds rigidity, prevents deformation, and distributes force evenly, ensuring the entire component works as intended. Steel backing is often treated with coatings (like zinc or paint) to boost corrosion resistance, making it suitable for harsh environments.

Key traits of steel backing include:

- High tensile strength (resists breaking under tension).

- Excellent heat resistance (handles temperatures up to 500°C or more).

- Good impact resistance (won’t crack under sudden force).

- Recyclability (reduces waste compared to some materials).

Steel Backing vs. Aluminum Backing

Aluminum is a lightweight alternative to steel, but their strength and durability differ significantly:

Strength

Steel backing has much higher tensile strength than aluminum. Steel can withstand about 400–800 MPa (megapascals) of force before breaking, while aluminum averages 70–300 MPa. This means steel backing resists stretching or tearing better under heavy loads—critical for parts like brake pads, which face intense pressure during use.

Aluminum, being softer, is more likely to deform under high stress. For example, in a car’s brake system, aluminum backing might bend during hard braking, reducing the friction pad’s effectiveness. Steel backing, by contrast, stays rigid, ensuring consistent contact between the pad and rotor.

Durability

- Heat resistance: Steel backing handles high temperatures better. Aluminum softens at around 200°C, making it unsuitable for hot environments like engine bays or brake systems (which reach 300–500°C). Steel remains stable even at these temperatures, avoiding warping or melting.

- Wear and corrosion: Aluminum is more corrosion-resistant than untreated steel, but steel backing can be coated (with zinc or epoxy) to match or exceed this. In wet or salty environments (like marine equipment), coated steel backing lasts longer than aluminum, which can still corrode over time in extreme conditions.

- Lifespan: In high-stress applications (e.g., industrial machinery), steel backing lasts 2–3 times longer than aluminum. Aluminum’s tendency to fatigue (weaken after repeated stress) shortens its life in parts that move or vibrate frequently.

Steel Backing vs. Brass Backing

Brass, an alloy of copper and zinc, is valued for its malleability and corrosion resistance, but it’s no match for steel backing in strength and durability.

Strength

Brass has a tensile strength of 200–500 MPa, lower than most steel (400–800 MPa). This makes brass backing unsuitable for heavy loads. For example, in hydraulic gaskets that seal high-pressure fluids, brass backing may deform, causing leaks. Steel backing, with its higher strength, maintains a tight seal even under extreme pressure.

Durability

- Wear resistance: Brass is softer than steel, so it wears down faster in parts that rub against other components (e.g., sliding gaskets). Steel backing’s hardness reduces wear, even with constant friction.

- Cost and longevity: Brass is more expensive than steel, and its shorter lifespan in high-stress uses makes it less cost-effective. Steel backing offers better durability at a lower price, making it preferred for bulk or long-term applications.

- Corrosion: Brass resists corrosion well in water or mild chemicals, but in acidic or high-salt environments (like coastal industrial plants), steel backing with anti-corrosion coatings (e.g., galvanized steel) performs equally well—at a lower cost.

Steel Backing vs. Plastic Backing

Plastic backing (e.g., nylon, polyester) is lightweight and cheap, but it lags far behind steel backing in strength and durability.

Strength

Plastic has very low tensile strength (20–100 MPa) compared to steel backing. It bends or breaks easily under even moderate stress. For example, plastic-backed brake pads in a small car may work for light use, but in a truck or SUV, the plastic would crack under the weight, leading to brake failure. Steel backing, by contrast, handles the load without deformation.

Durability

- Heat resistance: Plastic melts or warps at 100–200°C, making it useless in high-heat parts like engine gaskets or brake pads (which reach 300°C+). Steel backing remains stable at these temperatures.

- Environmental resistance: Plastic degrades over time when exposed to sunlight (UV rays) or chemicals (oils, solvents). Steel backing, especially coated varieties, resists these factors, lasting years longer.

- Practical use: Plastic backing is limited to low-stress, low-heat applications (e.g., lightweight consumer goods). Steel backing is necessary for any part that faces heavy use, heat, or harsh conditions.

Steel Backing vs. Composite Backing

Composite backing, made from materials like fiberglass-reinforced plastic (FRP) or carbon fiber, combines strength and lightness. But how does it compare to steel backing?

Strength

High-end composites can match or exceed steel’s tensile strength (up to 1,000 MPa for carbon fiber composites). However, this strength comes at a cost: composites are brittle and can shatter under sudden impacts (e.g., a dropped tool hitting a composite-backed part). Steel backing, while slightly less strong in some cases, is more flexible and resists impact better, bending rather than breaking.

Durability

- Cost and repair: Composites are expensive to produce, making them impractical for mass-produced parts (e.g., standard brake pads). Steel backing is cheaper and easier to repair or replace.

- Consistency: Composite quality varies more than steel, which is manufactured to strict standards. In critical applications (e.g., aerospace gaskets), steel backing’s reliability makes it preferable, even if composites offer similar strength.

- Extreme environments: In very high temperatures (over 500°C), some composites degrade, while steel backing (especially heat-treated steel) remains stable. In cold conditions, composites may become brittle, whereas steel retains its flexibility.

When to Choose Steel Backing

Steel backing is the best choice in applications that require:

- High strength to handle heavy loads or pressure.

- Resistance to heat (over 200°C) or extreme temperatures.

- Long lifespan in harsh environments (salt, chemicals, vibration).

- Cost-effectiveness for bulk or long-term use.

Common uses include:

- Brake pads and clutch plates (needs heat resistance and strength).

- Industrial gaskets and seals (high pressure, chemical exposure).

- Automotive and machinery parts (vibration, heavy loads).

FAQ

What is steel backing used for?

Steel backing reinforces parts like brake pads, gaskets, and friction materials, providing strength and stability in high-stress, high-heat applications.

Is steel backing stronger than aluminum backing?

Yes. Steel backing has higher tensile strength (400–800 MPa) than aluminum (70–300 MPa), making it better for heavy loads and high stress.

Does steel backing rust easily?

Untreated steel can rust, but most steel backing is coated (galvanized or painted) to resist corrosion. This makes it durable in wet or salty environments.

Is composite backing better than steel backing?

Composite backing can match steel in strength but is more expensive, brittle, and less reliable in extreme conditions. Steel backing is better for most practical, high-stress uses.

How long does steel backing last?

In industrial or automotive parts, steel backing typically lasts 5–10 years, 2–3 times longer than aluminum or plastic in the same applications.

Is steel backing heavier than other materials?

Yes, steel is denser than aluminum, brass, or plastic. But its strength and durability often outweigh the weight trade-off in critical parts.

Can steel backing be used in high-temperature environments?

Yes. Steel backing handles temperatures up to 500°C+ (depending on the steel type), making it ideal for brake pads, engine parts, and industrial furnaces.

Table of Contents

- How Does Steel Backing Compare to Other Materials in Terms of Strength and Durability?

- What Is Steel Backing?

- Steel Backing vs. Aluminum Backing

- Steel Backing vs. Brass Backing

- Steel Backing vs. Plastic Backing

- Steel Backing vs. Composite Backing

- When to Choose Steel Backing

-

FAQ

- What is steel backing used for?

- Is steel backing stronger than aluminum backing?

- Does steel backing rust easily?

- Is composite backing better than steel backing?

- How long does steel backing last?

- Is steel backing heavier than other materials?

- Can steel backing be used in high-temperature environments?