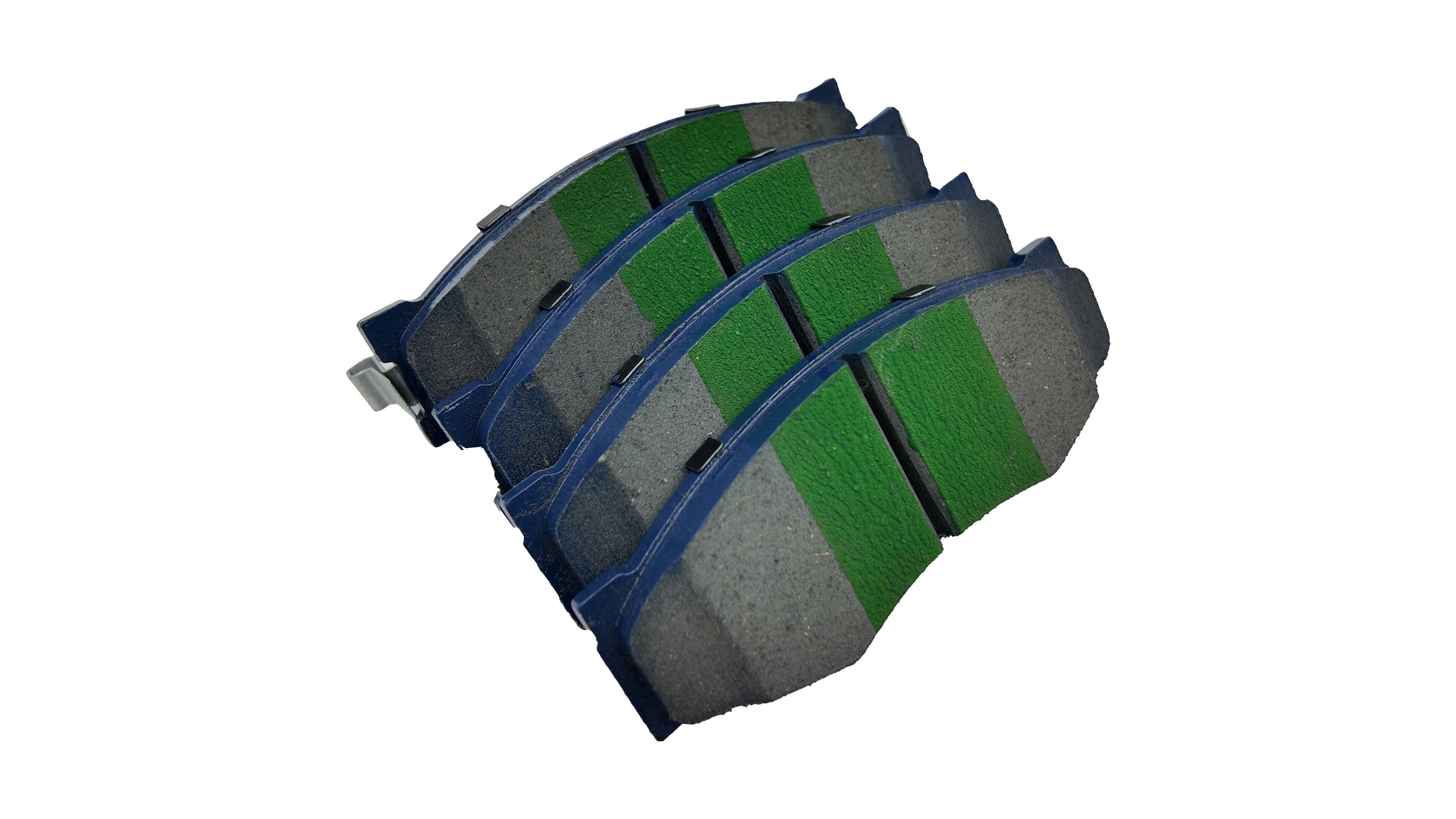

automotive brake pads

Automotive brake pads are crucial safety components designed to create friction with the brake rotor, effectively slowing or stopping a vehicle. These essential components consist of a backing plate and friction material, engineered to withstand extreme temperatures and pressures during braking operations. Modern brake pads incorporate advanced composite materials, including metallic, ceramic, and organic compounds, each offering specific performance characteristics. The friction material is precisely formulated to provide optimal braking performance across various driving conditions, from everyday commuting to high-performance applications. Contemporary brake pads feature sophisticated noise reduction technology, including chamfered edges and multi-layer shims, ensuring quiet operation. They also incorporate wear indicators that alert drivers when replacement is necessary, maintaining safety standards. The manufacturing process involves high-pressure molding and heat treatment to ensure structural integrity and consistent performance throughout the pad's service life. These components undergo rigorous testing for heat resistance, durability, and stopping power, meeting or exceeding international safety standards. Brake pads are vehicle-specific, with different formulations available for passenger cars, SUVs, trucks, and performance vehicles, ensuring optimal braking efficiency for each application.